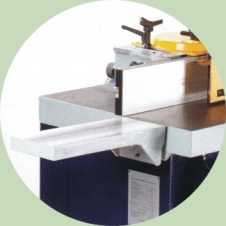

Mpower 512TS Backward Tilt Spindle Moulder

- Description

- About Conway Saw

Description

The advantages of backward tilting spindle

- Safer working. Machining from under the workpiece makes for optimum protection.

- Possibility of machining any sizes of workpiece.

- Full use of pressure guards or power feeder without regard to the obstruction.

- Minimizing the load on spindle bearings to ensure the durability and precise moulding profile.

- Perfect dust collection. Wood chips are directed into exhaust outlets.

Outstanding Features

- Working safely, in compliance with the latest safety regulation enforced.

- Hardened, ground and electronically balanced spindle in special steel guarantees the absolute absence of vibrations.

- Spindle interchangeable and collets available for use of router bits.

- Cast iron table of great solidity with ground surface.

- Sliding table in cast iron glides on six adjustable ball bearings for smooth table travel for the long term.

- Heavy cast iron, extruded aluminium fence assembly is fully adjustable.

| Technical | |

|---|---|

| Dimensions of working table | 1000 x 800mm |

| Working table height | 900mm |

| Spindle vertical stroke | 180mm |

| Max. tool diameter below table top | 210mm |

| Max. tool diameter above table top | 335mm |

| Spindle speed | 3000 / 4000 / 6000 / 8000 / 10,000 |

| Rotation | Forward and reverse |

| Motor Power | 7.5HP |

| Sliding table dimensions (MS) | 1000 x 260mm |

| Working stroke of the slide (MS) |

940mm |

| Spindle tilting | 940° |

Conway Saw are one of the UK’s leading woodworking machinery specialists offering a range of new and used wood cutting machines. We sell a variety of machines including up cut saws, bandsaws, radial arm saws, spindle moulders and edgebanders. We also sell a number of woodworking consumables including head return springs, glue applicators, Wadkin spares and other tooling such as rubber feed rollers, sash cramps and mortising tools.