Houfek Bulldog 5 Wide Belt Sanding Machine

Call For Price

Original construction of sander Buldog 5 is designed by HOUFEK Inc. for customers, who ask for simplicity, reliability and quality .

Sanding masive, veneered finish and varnish is easy with Buldog 5.

Buldog 5 excels in robust design, simply operating and high comfort. Many thousands of these sanders are working around the world for their satisfied customers.

- Description

- About Conway Saw

Description

Wide belt sanders Buldog Line are made as modular construction. This machine can assembled in requirements of our customers. HOUFEK machines can be equipped in these units and their combinations according customer needs.

- sanding unit with working roller

- sanding unit with working roller and sanding pad

- sanding unit with pad

- planing rollers

- special unit for assembling sanding, polishing and fabric tools

- optional unit for assembling polishing, fabrics and cleaning tools – assembling of this unit is on back side of the machine

| Technical | R / C / RR / RC / FC / RRR / RRC / FRC | ||||

|---|---|---|---|---|---|

| 910 | 1010 | 1100 | 1300 | ||

| Working width | mm | 910 | 1010 | 1100 | 1300 |

| Height of workpiece | mm | 3 – 160 | 3 – 160 | 3 – 160 | 3 – 160 |

| Diameter of working roller | mm | 160 | 160 | 160 | 160 |

| Width of sanding belt | mm | 930 | 1030 | 1120 | 1320 |

| Length of sanding belt | mm | 1900 | 1900 | 1900 | 1900 |

| Speed of sanding belt | m/s | 18 | 18 | 18 | 18 |

| Speed of feeding belt | m/min | 4,5 / 9 | 4,5 / 9 | 4,5 / 9 | 4,5 / 9 |

| Motor power for sanding belt | kW | 11 – 18 | 11 – 18 | 11 – 18 | 11 – 18 |

| Motor power for feeding belt | kW | 0,43 / 0,3 | 0,43 / 0,3 | 0,43 / 0,3 | 0,43 / 0,3 |

| Motor power for table lift | kW | 0,18 | 0,18 | 0,18 | 0,18 |

| Supply voltage | V/Hz | 3/N/PE 400V/50Hz | 3/N/PE 400V/50Hz | 3/N/PE 400V/50Hz | 3/N/PE 400V/50Hz |

| Air pressure consumption | l/min | 20 | 20 | 20 | 20 |

| Input operated press | bar | 5,5 | 5,5 | 5,5 | 5,5 |

| Input operated press for belt blower | bar | 8 | 8 | 8 | 8 |

| Diameter of exhausting | mm | 150 | 150 | 150 | 180 |

| Capacity of exhausting | m3/hr | m3/hr | 3500 | 4000 | 5000 |

| Speed of exhausted air | m/s | 20 | 20 | 20 | 20 |

Parameters are approximate depend on the type and configuration of the machine.

Standard equipment

- rubbered roller D=160 mm, 90Sh

- length of sanding belt 1900 mm

- motorized lift of work-table

- automatic star / delta switching

- ampermeter for sanding motor

- centering of sanding belt with infrared sensor

- table positioner

- electronic measuring of table position with digital display

- two speeds of feeding belt 4,5/9 m/min

- rubberized press rollers

- pneumatic disc brake of main motor

- antinoiseness protection

- CE electric and safety standard

Optional equipment

- 20HP ( 15kW ) motor

- 25HP ( 18,5 kW ) motor

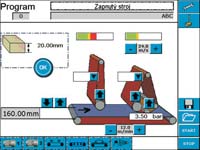

- NC machine operating color Touchscreen 10,4″

- Two speed of sanding belt – 9/18 m/sec

- Two speeds for lift of table

- Steel roller instead of rubbered D=160 mm

- Rubbered roller D=160 mm, 30 Sh

- Rubbered roller D=160 mm, 45 Sh

- Rubbered roller D=160 mm, 60 Sh

- Adaptation for length of sandig belt 2200 mm (high of machine 200mm)

- Frequence converter of feeding belt speed 3 – 12m/min

- Frequence converter of main motor – belt speed 3-20m/s

- Pressure ledge for grinding short workpiece – 1 couple

- Automatic centering of feeding belt

- Automatic table positioner

- Pneumatic timed blower for cleaning 1 sanding belt

- Pneumatic timed blower with moving jets of 1 aggregate

- Orbital blower of workpiece

- Front extension table

- Rear extension table

- 1st working roller with timed ascent/descent

- Maximum-decrease limitation of workpiece

- Module for clearing of workpiece by rotating textile or nylon brush 140 mm diameter, 1,5 HP

- Vacuum table

- Vacuum pump

- Exhausting clappet D=150 mm (R,C)

- Exhausting clappet D=180 mm (R,C only for width 1300mm)

- Special voltage 3Ph, 230/ 60Hz

Conway Saw are one of the UK’s leading woodworking machinery specialists offering a range of new and used wood cutting machines. We sell a variety of machines including up cut saws, bandsaws, radial arm saws, spindle moulders and edgebanders. We also sell a number of woodworking consumables including head return springs, glue applicators, Wadkin spares and other tooling such as rubber feed rollers, sash cramps and mortising tools.