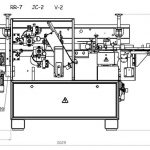

Lange Maschinen Bau B 85K Edge Banding Machine

Call For Price

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from:

0.4 – 2.0mm and of 8 – 40mm work piece thickness.

- Description

- About Conway Saw

Description

One-sided automatic edge banding machine with direct glue application to straight workpieces, HF-cut-off saw station, HF-top and bottom milling unit, chain feed, double roller top pressure and work piece support. For ABS, PVC, melamine and strong wood veneer roll material as well as fixed lengths from:

0.4 – 2.0mm and of 8 – 40mm work piece thickness.

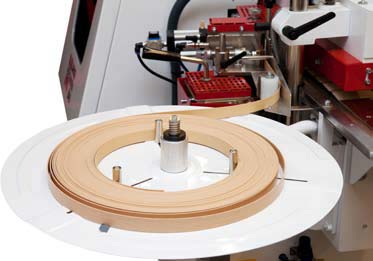

- Automatic edge feeding for roller material over turntable D = 600mm

- Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 2 kg, leak-proof with glue supply from below (excess glue automatically flows back into the glue pot).

Glue roller allows exact dosage of glue.

Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer period and is still turned on) - Pneumatically operated cut-off knife from roll material up to 2mm edge thickness

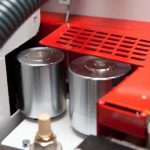

- Pressure unit consisting of one driven pressure roller synchronized with glue spreading roller and one adjustable pressure roller with spring tension for a nearly invisible joint of the edge material with the work piece

- High-frequency cut-off saw equipped with HF motor 0.20 kW, 12,000 rpm , 2 saw blades and high-precision linear guides ensure a clean and precise saw cut

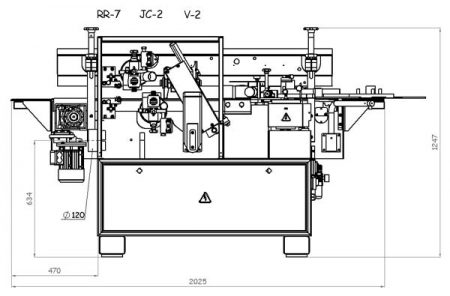

- High-frequency top and buttom milling station, 2 powerful 0.27 kW high-frequency motors with HM-WPL special millers; suitable for radius and bevel milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle Ø 120mm; height adjustment of the upper aggregate with the top roll pressure.

- Operating panel (PLC) with LCD display and key field controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis.

- Glue scraper unit: removes eventual glue rests with a slight draw cut from the glue joint of the work piece surface.

| Technical | |

|---|---|

| Workpiece Thickness | 8 – 40 mm |

| Workpiece Width Min. | approx. 75mm |

| Workpiece Length Min. | approx. 120mm |

| Edging Thickness | 0.4 – 2.0mm |

| Max. Edge Thickness | = Workpiece Thickness 4mm (2 2) |

| Electircal Connection | 400V – 50Hz – 3HP N |

| Total Load | 2.5Kw |

| Feed Speed | 5.5m/min |

| Air Connection | 6 Bar |

Conway Saw are one of the UK’s leading woodworking machinery specialists offering a range of new and used wood cutting machines. We sell a variety of machines including up cut saws, bandsaws, radial arm saws, spindle moulders and edgebanders. We also sell a number of woodworking consumables including head return springs, glue applicators, Wadkin spares and other tooling such as rubber feed rollers, sash cramps and mortising tools.